Pallet Shuttle System for Fast Turnaround Packaging Storage

A leading manufacturer of plasterboard and gypsum-based products required an improved storage solution for packaging materials, which were previously stored solely at floor level.

Operating a highly advanced site that spans from raw material extraction to production and distribution, the client needed a tailored storage system to support seamless operations. Teccon was selected to consult, specify, and install a comprehensive warehouse solution that would enhance production flow and logistics efficiency.

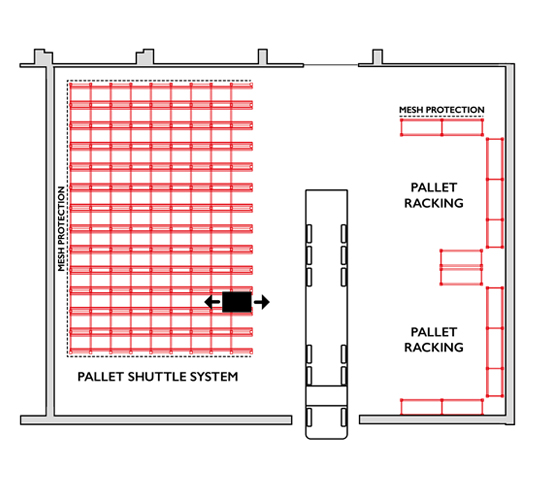

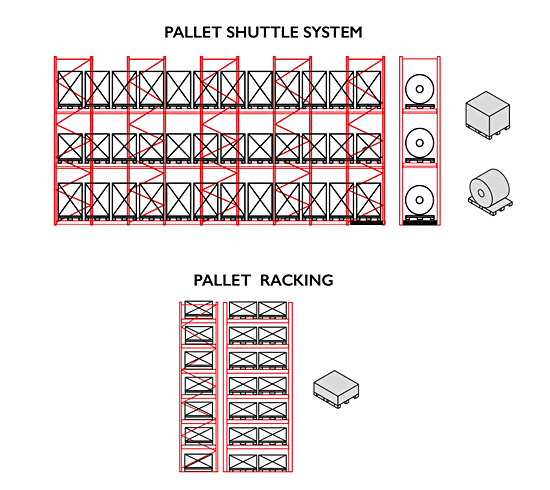

After a thorough design and consultation phase, the project was successfully delivered with a semi-automated pallet shuttle system and two distinct racking configurations for both palletised packaging and spools.

Challenge

High Volume, Fast Turnaround

The warehouse was solely dedicated to handling two packaging types, including palletised spools, with rapid turnover.

These palletised bags were required in large quantities, demanding a high-throughput storage and retrieval system.

Any disruption in packaging availability could halt national product distribution, creating significant bottlenecks and logistical setbacks.

Solution

Semi-Automated Pallet Shuttle System

The Dexion semi-automated Pallet Shuttle System was installed for efficient pallet handling. Pallets are loaded onto the shuttle within each bay, which autonomously retrieves or stores them as required.

About the Pallet Shuttle System

The Pallet Shuttle system is a semi-automated, high-density storage solution that operates similarly to drive-in or pallet-flow setup although it removes the need for MHE to enter the aisles.

This cost-effective and time-saving solution is a highly efficient alternative to live storage and drive-in racking. It works either as First in, First out (FIFO) or as Last in, First out (LIFO), and suitable for all applications.

The Pallet Shuttle system offers the following standard benefits:

- Cost-effective and time-saving, without the need for special forklifts.

- Low risk of equipment damage or employee injury.

- Fast and sustainable, automatically handling pallet picking and retrieval.

- Provides more effective, high-density storage.

- Can pick up, deposit, and reorganise pallets with great precision.

- Operates within a range of operating temperatures: ST: 0°C to +45°C, BZ: -1°C to -30°C, or Hybrid model suitable for both ranges.

- Available in different models designed for various pallet configurations.

- Designed in accordance with the European Directive 2006/42/EG and DIN EN 15095.

Maximised Storage Density

Utilising the warehouse’s vertical space, Teccon implemented a three-tier, 13-bay shuttle system using Dexion P90 racking with a depth of 12 pallets deep, enabling storage of up to 468 pallets.

Compared to the original floor-level setup, this represented a fourfold increase in capacity. Using the shuttle system enabled the end user to put different size pallets into any location allowing a better storage utilisation.

Planning and Roll-out

This turn-key solution was completed in 8 weeks, delivering the client a ready to go solution for consistent quality throughout.

Our proven systems, clear communication, and dedication to the client’s operational needs demonstrate why Teccon continues to inspire customer confidence and remains the first choice for storage solutions.

Specifications

Dexion P90 Pallet Racking

Mesh Partitioning

Pallet Racking Protection